2017 New Style Low Melt Polyester Staple Fiber Use For Bonding - Polyvinyl Alcohol – Haitung

2017 New Style Low Melt Polyester Staple Fiber Use For Bonding - Polyvinyl Alcohol – Haitung Detail:

MAIN APPLICATIONS

In fiber fabrication

Two important applications of PVA is to be used as vinylon feedstock and sizing agent for textile.As raw material of vinylon fiber, has the advantages of being high in strength, moisture absorption, abrasion resistance, sunlight resistance, corrosion resistance and white in color. It can also be spun with cotton, wool and viscose fiber or purely spun with itself.As sizing agent for textile, It will not corrode or deteriorate with a good adhesion to cotton, hemp, polyester and viscose fiber.

Pulp & PaperPVA has found wide use in the treatment of paper surface as it has excellent adhesiveness and dispersibility and will not affect the property of other binders used in combination. The advantages of PVA using:Surface strength (printability);Strength along Z-axis(paper internal strength);Folding resistance;Abrasive resistance;Improved smoothness;Improved surface glossiness;Raised resistance to oil and solvent (barrier property).

Emulsion Stabilizer & Binder

PVA can be widely used as protective colloid or thickener for the emulsion polymerization of vinyl acetate (VAc) or VAc/ acrylate. has the following characteristics: excellent adhesiveness;ncreased initial tack and drying rate while used with filler;excellent resistance to oil;outstanding film strength;enduring and stable performance.

Film

PVA can be used to produce water soluble film and water-resistance film.PVA is available in formed products which highlight the inherent features of PVA,namely, high tensile strength, resistance to organic solvent and air tightness.They are both widely used in the package industry, not only for textile, but also for chemicals, food, daily chemicals, agricultural chemicals, dyestuff, and etc.

Dispersion Stabilizer

PVA, which is excellent in colloid protection and has superior surface activity,is often used as dispersion stabilizer for suspension polymerization of vinyl chloride monomer (VCM). The performance of PVC resin can be greatly optimized by selecting a suitable PVA grade with proper degree of polymerization and hydrolysis

PVA Grades & Specifications

|

New |

Hydrolysis |

Volatiles |

Viscosity |

Ash |

PH |

Purity |

|

Name |

(mol%) |

(%) |

(mpa.s) |

(wt%) |

Value |

(wt%) |

|

088-03 |

87.0 – 89.0 |

≤5.0 |

3.0-4.0 |

≤0.7 |

5-7 |

≥93.0 |

|

088-04 |

87.0 – 89.0 |

≤5.0 |

4.0-4.5 |

≤0.7 |

5-7 |

≥93.0 |

|

098-04 |

98.0-98.8 |

≤5.0 |

4.0-5.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-05 |

87.0 – 89.0 |

≤5.0 |

4.5-6.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-05 |

98.0-99.0 |

≤5.0 |

5.0-6.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-10 |

97.0-99.0 |

≤5.0 |

8.0-12.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-13 |

87.0 – 89.0 |

≤5.0 |

12.0-14.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-15 |

98.0 -99.0 |

≤5.0 |

13.0-17.0 |

≤0.5 |

5-7 |

≥93.5 |

|

093-16 |

92.5-94.5 |

≤5.0 |

14.5-18.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-20 |

98.0-99.0 |

≤5.0 |

18.0-22.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-20 |

87.0 – 89.0 |

≤5.0 |

20.5-24.5 |

≤0.4 |

5-7 |

≥93.5 |

|

092-20 |

91.0-93.0 |

≤5.0 |

21.0-27.0 |

≤0.5 |

5-7 |

≥93.5 |

|

096-27 |

96.0-98.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-27 |

98.0 – 99.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-26 |

87.0 – 89.0 |

≤5.0 |

24.0-28.0 |

≤0.5 |

5-7 |

≥93.5 |

|

095-28 |

94.0-96.0 |

≤5.0 |

26.0-30.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-30 |

98.0 – 99.0 |

≤5.0 |

28.0-32.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-35 |

87.0 – 89.0 |

≤5.0 |

29.0-34.0 |

≤0.3 |

5-7 |

≥93.5 |

|

088-50 |

87.0 – 89.0 |

≤5.0 |

45.0-55.0 |

≤0.3 |

5-7 |

≥93.5 |

|

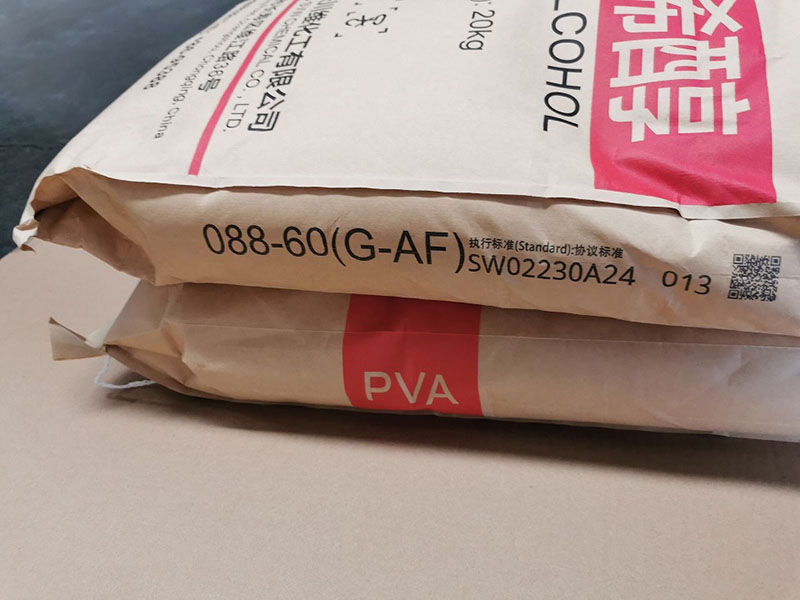

088-60 |

87.0 – 89.0 |

≤5.0 |

50.0-58.0 |

≤0.3 |

5-7 |

≥93.5 |

|

097-60 |

96.0-98.0 |

≤5.0 |

56.0-66.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-60 |

98.0 – 99.0 |

≤5.0 |

58.0-68.0 |

≤0.5 |

5-7 |

≥93.5 |

|

097-70 |

96.0 – 98.0 |

≤5.0 |

66.0-76.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-75 |

98.0 – 99.0 |

≤5.0 |

70.0-80.0 |

≤0.5 |

5-7 |

≥93.5 |

Our Shipments

Our Warehouse

We have more than 3000m2 warehouse for PVA to make sure the stable supply and competitive price always.

Product detail pictures:

Related Product Guide:

PVA Fiber Market 2018: By Product Type, Segmentation, Market Potential, Influential Trends, And The Challenges, And Forecast To 2023 | Chinese Methyl Acrylate (Ma) Supplier

Online Blockchain PLC buys 35% interest in Encryptid Gaming Inc | Chinese Methyl Acrylate (Ma) Supplier

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for 2017 New Style Low Melt Polyester Staple Fiber Use For Bonding - Polyvinyl Alcohol – Haitung , The product will supply to all over the world, such as: Puerto Rico , Qatar , Malawi , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.