Rapid Delivery for Paraffin Wax Pellets - Polyvinyl Alcohol – Haitung

Rapid Delivery for Paraffin Wax Pellets - Polyvinyl Alcohol – Haitung Detail:

PRODUCER:SINOPEC

PVA has many exceptional properties such as water solubility, fiber-forming property, adhesiveness, film-forming property, emulsion stability, dispersion stability, resistance to oil, acid, and alkali, chemical reactivity, biodegradability, as well as meltability (or thermoplasticity) and many unique and special properties through modification.PVA is widely used in many industries like textile, papermaking, construction, chemicals, printing, packaging, pharmaceuticals, detergents & cosmetics, agriculture, ceramics, iron & steel, electronics, electrolysis, electroplating, and etc.

Application:

PVA, which is excellent in colloid protection and has superior surface activity, is often used as dispersion stabilizer for suspension polymerization of vinyl chloride monomer (VCM). The performance of PVC resin can be greatly optimized by selecting a suitable PVA grade with proper degree of polymerization and hydrolysis.

Emulsion Stabilizer & Binder

PVA can be widely used as protective colloid or thickener for the emulsion polymerization of vinyl acetate (VAc) or VAc/ acrylate. has the following characteristics: excellent adhesiveness;increased initial tack and drying rate while used with filler;excellent resistance to oiloutstanding film strength;enduring and stable performance.

Fiber fabrication

Two important applications of PVA is to be used as vinylon feedstock and sizing agent for textile.As raw material of vinylon fiber, has the advantages of being high in strength, moisture absorption, abrasion resistance,sunlight resistance, corrosion resistance and white in color. It can also be spun with cotton, wool and viscose fiber or purely spun with itself.As sizing agent for textile, It will not corrode or deteriorate with a good adhesion to cotton, hemp, polyester and viscose fiber.

Film

PVA can be used to produce water soluble film and water-resistance film. PVA is available in formed products which highlight the inherent features of PVA, namely, high tensile strength, resistance to organic solvent and air tightness.They are both widely used in the package industry, not only for textile, but also for chemicals, food, daily chemicals, agricultural chemicals, dyestuff, and etc.

Pulp & Paper

PVA has found wide use in the treatment of paper surface as it has excellent adhesiveness and dispersibility and will not affect the property of other binders used in combination. The advantages of PVA using:Surface strength (printability);Strength along Z-axis(paper internal strength);Folding resistance;Abrasive resistance;Improved smoothness;Improved surface glossiness;Raised resistance to oil and solvent (barrier property).

PVA Grades & Specifications

|

New Name |

Hydrolysis (mol%) |

Volatiles (%) |

Viscosity (mpa.s) |

Ash (wt%) |

PH Value |

Purity (wt%) |

|

088-03 |

87.0 – 89.0 |

≤5.0 |

3.0-4.0 |

≤0.7 |

5-7 |

≥93.0 |

|

088-04 |

87.0 – 89.0 |

≤5.0 |

4.0-4.5 |

≤0.7 |

5-7 |

≥93.0 |

|

098-04 |

98.0-98.8 |

≤5.0 |

4.0-5.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-05 |

87.0 – 89.0 |

≤5.0 |

4.5-6.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-05 |

98.0-99.0 |

≤5.0 |

5.0-6.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-10 |

97.0-99.0 |

≤5.0 |

8.0-12.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-13 |

87.0 – 89.0 |

≤5.0 |

12.0-14.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-15 |

98.0 -99.0 |

≤5.0 |

13.0-17.0 |

≤0.5 |

5-7 |

≥93.5 |

|

093-16 |

92.5-94.5 |

≤5.0 |

14.5-18.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-20 |

98.0-99.0 |

≤5.0 |

18.0-22.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-20 |

87.0 – 89.0 |

≤5.0 |

20.5-24.5 |

≤0.4 |

5-7 |

≥93.5 |

|

092-20 |

91.0-93.0 |

≤5.0 |

21.0-27.0 |

≤0.5 |

5-7 |

≥93.5 |

|

096-27 |

96.0-98.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-27 |

98.0 – 99.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-26 |

87.0 – 89.0 |

≤5.0 |

24.0-28.0 |

≤0.5 |

5-7 |

≥93.5 |

|

095-28 |

94.0-96.0 |

≤5.0 |

26.0-30.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-30 |

98.0 – 99.0 |

≤5.0 |

28.0-32.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-35 |

87.0 – 89.0 |

≤5.0 |

29.0-34.0 |

≤0.3 |

5-7 |

≥93.5 |

|

088-50 |

87.0 – 89.0 |

≤5.0 |

45.0-55.0 |

≤0.3 |

5-7 |

≥93.5 |

|

097-60 |

96.0-98.0 |

≤5.0 |

56.0-66.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-60 |

98.0 – 99.0 |

≤5.0 |

58.0-68.0 |

≤0.5 |

5-7 |

≥93.5 |

|

097-70 |

96.0 – 98.0 |

≤5.0 |

66.0-76.0 |

≤0.5 |

5-7 |

≥93.5 |

| 098-75 | 98.0 – 99.0 |

≤5.0 |

70.0-80.0 |

≤0.5 |

5-7 |

≥93.5 |

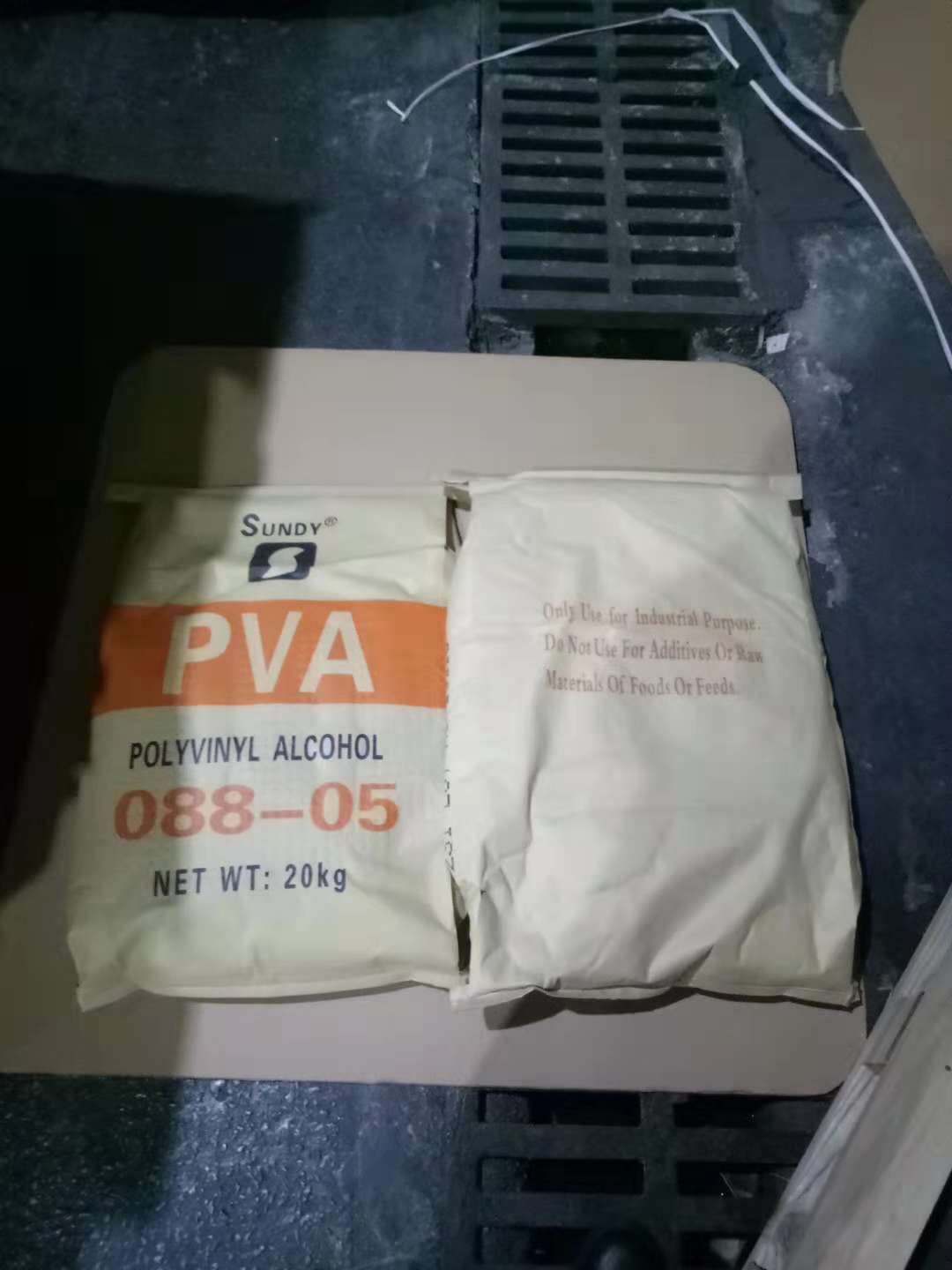

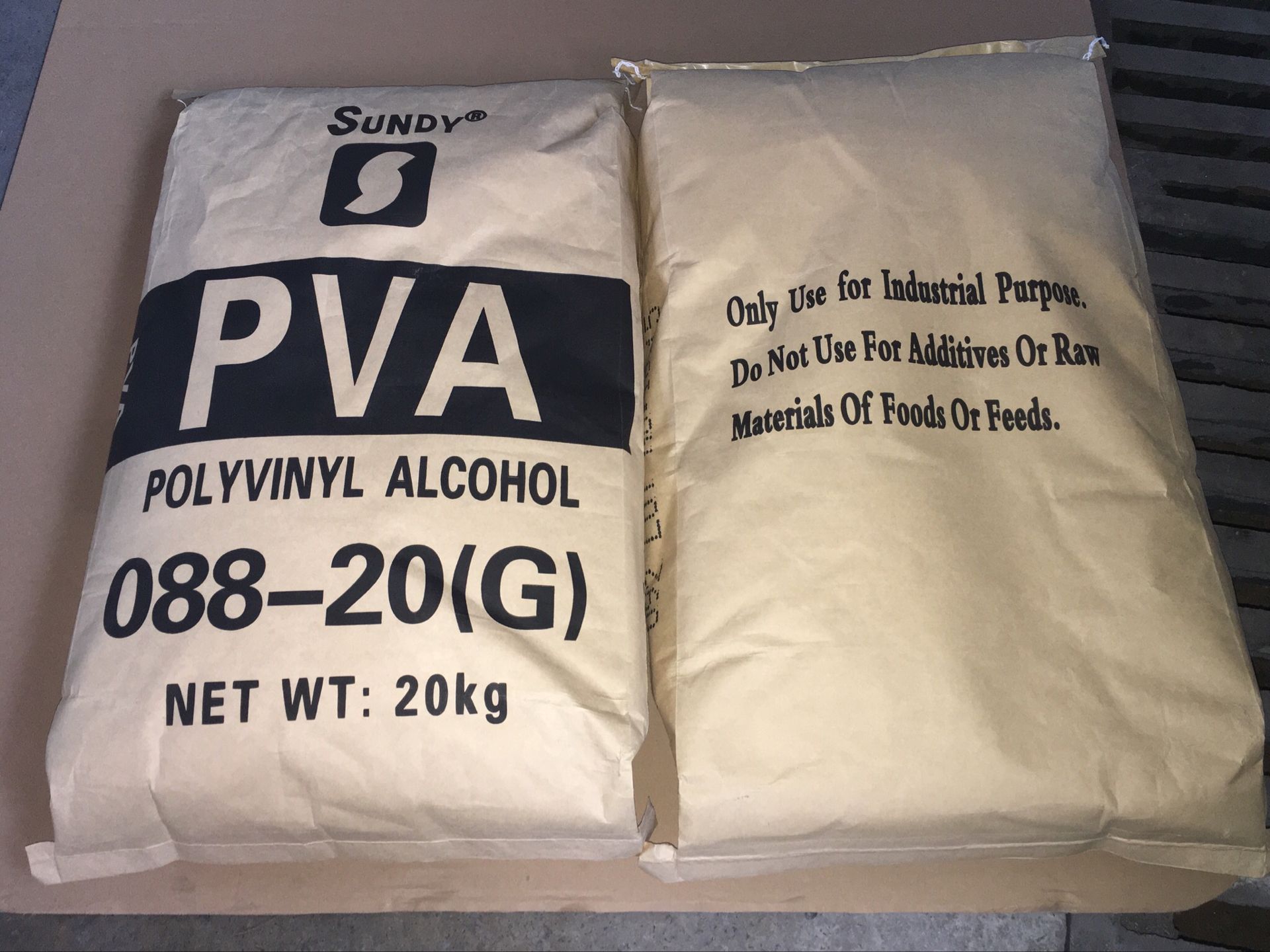

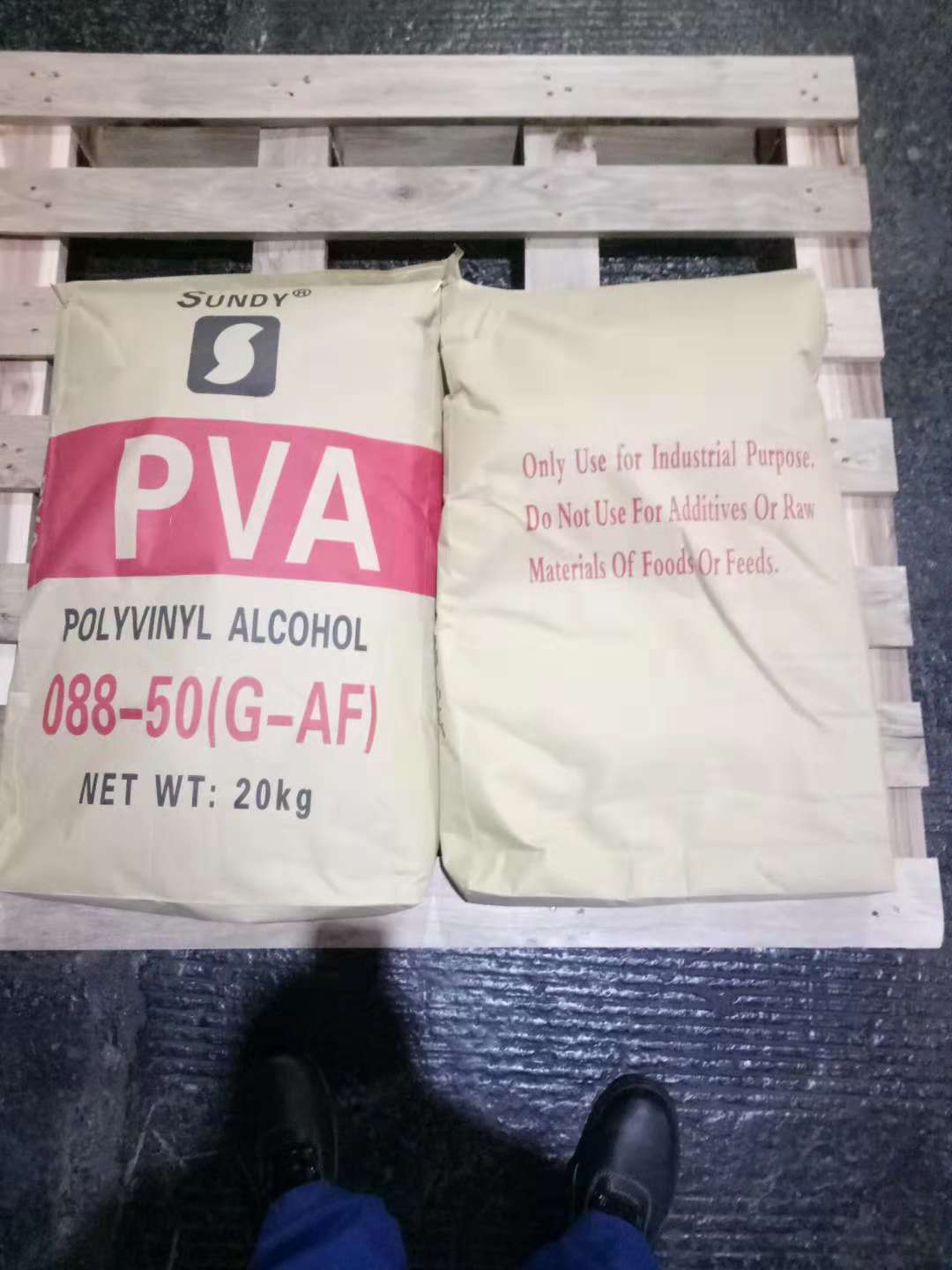

Product detail pictures:

Related Product Guide:

Alin Burcea: Cam toată lumea oferă acum România și Republica Moldova la pachet ~ InfoPrut | Chinese Pva Fiber Supplier

NMC Health plc Continuous execution of 2017 enhanced strategy | Chinese Pva Fiber Supplier

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Rapid Delivery for Paraffin Wax Pellets - Polyvinyl Alcohol – Haitung , The product will supply to all over the world, such as: Vancouver , Guyana , Bhutan , Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!