Special Design for 1.4-butanediol Monovinyl Ether 98%min - SBS(styrene –butadiene block copolymer) – Haitung

Special Design for 1.4-butanediol Monovinyl Ether 98%min - SBS(styrene –butadiene block copolymer) – Haitung Detail:

PROPERTIES AND APPLICATIONS

Styrene-butadiene block copolymers are an important class of synthetic rubbers. The two most common types are linear and radial triblock copolymers having rubber center blocks and polystyrene end blocks. SBS elastomers combine the properties of a thermoplastic resins with those of butadiene rubber. The hard, glassy styrene blocks provide mechanical strength and improve the abrasion resistance, while the rubber mid-block provides flexibility and toughness.

In many regards, SBS elastomers with a low styrene content have properties that are similar to those of vulcanized butadiene rubber but can be molded and extruded using conventional thermoplastic processing equipment. However, SBS is less resilient than chemically crosslinked (vulcanized) butadiene rubber and thus, does not recover as efficiently from deformation as vulcanized diene elastomers.

SBS rubbers are often blended with other polymers to enhance their performance. Often oil and fillers are added to lower cost and to further modify their properties.

Application

SBS are used in many different industries: automotive, bitumen modification, HIPS, shoe soles and masterbatch. Synthetic rubber is often preferred over natural rubber because it is higher in purity and easier to handle. One of BassTech’s core products, styrene-butadiene styrene (SBS), is a common synthetic rubber used in industrial manufacturing.

1. Styrene-butadiene styrene is classified as a thermoplastic elastomer.

As a thermoplastic elastomer, SBS is easily processed and reprocessed when heated. Upon heating, it acts like plastic and is very workable. Its structure (block copolymer with two polystyrene chains) allows for a combination of hard plastic and elastic properties.

2. Compared to traditional vulcanized rubber, using styrene-butadiene styrene can help reduce production costs.

It is recyclable, abrasion-resistant and does not require vulcanizing. SBS ages well and does not wear easily, minimizing the need for repairs and making it a cost-effective component of roofing products.

3. Styrene-butadiene styrene is very suitable for roofing applications.

SBS is widely used in roofing applications such as bitumen modification, liquid seal materials and waterproof coatings. In cold temperatures, SBS remains strong, flexible and resistant to moisture. In addition to roofing, SBS is used in paving, sealants and coatings to add cold flexibility and reduce destructive crack propagation. As an asphalt modifier, SBS prevents potholes and cracks typically caused by thermal shock.

4. Styrene-butadiene styrene is a popular material for footwear manufacturers.

SBS is an excellent material in footwear manufacturing for many of the same reasons that make it ideal for roofing. In shoe soles, styrene-butadiene styrene contributes to a strong yet flexible product that can be waterproofed.

Main Physical Properties of SBS Products

| Grade | Structure | S/B | Tensile Strength Mpa |

Hardness Shore A |

MFR (g/10min, 200℃, 5kg) |

Toluene Solution Viscosity at 25℃ and 25%, mpa.s |

| YH-792/792E | Linear | 38/62 | 29 | 89 | 1.5 | 1,050 |

| YH-791/791E | Linear | 30/70 | 15 | 70 | 1.5 | 2,240 |

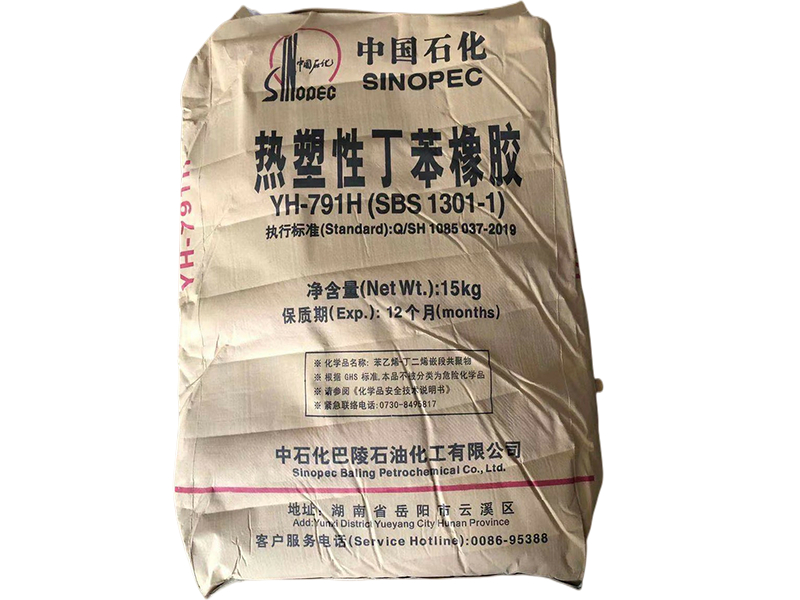

| YH-791H | Linear | 30/70 | 20 | 76 | 0.1 | |

| YH-796/796E | Linear | 23/77 | 10 | 70 | 2 | 4,800 |

| YH-188/188E | Linear | 34/66 | 26 | 85 | 6 | |

| YH-815/815E | Star-shaped | 40/60 | 24 | 89 | 0.1 | |

| Road modification -2# | Star-shaped | 29/71 | 15 | 72 | 0.05 | 1,050* |

| YH-803 | Star-shaped | 40/60 | 25 | 92 | 0.05 | |

| YH-788 | Linear | 32/68 | 18 | 72 | 4-8 | |

| YH-4306 | Star-shaped | 29/71 | 18 | 80 | 4-8 |

Note: The item marked * is viscosity of 15% toluene solution.

“E” represents environment-friendly product.

Product detail pictures:

Related Product Guide:

Polymetal International plc successfully closes new US$250 million bank loan with Alfa-Bank | Vinyl Acetate Icis Report

Wood Group Plc Secures $53m of contracts with ADNOC Onshore | Sinopec Pp Pe Ps Abs Factory

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Special Design for 1.4-butanediol Monovinyl Ether 98%min - SBS(styrene –butadiene block copolymer) – Haitung , The product will supply to all over the world, such as: Amsterdam , Denver , Jamaica , Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.